ConduVec - Continuous combi cooker

The most flexible combi oven which combines conduction with convection and non-stick conveyors. ConduVec is a flexible system for ground meat, bone-in and irregular shaped products such as chicken wings or chicken legs.

The perfect combination of convection and conduction heat to provide an incomparable homemade result

ConduVec is a continuous combi cooker that combines two different heating techniques. It conveys products on solid non-stick PTFE belts. The products are directly heated by conduction from underneath while broiler grills (electrical resistances) simultaneously provide dry convection heat from above. It is the most flexible system in the food industry.

Because we are not using any steam or forced air during the cooking process, we ensure a Maillard reaction and a nice browning and the product maintains its natural shape. CelsiusFOOD’s unique technology allows to keep the juices of meat products on the heated conveyor during the cooking process like the drippings contained in a fry-pan. This thermal process gives products an incomparable taste of homemade food!

A combi oven that uses dry air to give you the best roasted products

ConduVec – continuous combi cooker generates dry heat from broilers without stirring the air. Our technology uses static air. Unlike hairdryers, which are designed to remove moisture by blowing hot air, convection broilers in static air prevent your product from dehydrating.

sBy using static air, your food product loose less weight during the cooking process. By keeping air still, broilers eliminate the need to add wet steam to compensate the loss of moisture. With the ConduVec - Continuous combi cooker, you will get the perfect browning effect for your roasted products.

The distance between the broiler grills and the products, the cooking time and the temperature can be set and saved in our latest generation of HMI. You can add up to 300 recipes! To save on energy, water and production costs, the system uses steam to wash the Teflon belt during operation.TECHNICAL INFORMATION

- Available widths: 600, 1,000, 1,200 mm

- Distance from 60 to 400 mm

- Stainless steel heating plates

- Electric or thermal oil heating (heating plates only)

- Electric broiler grills

- Max. temp: 260°C

- Max. temp. broiler grills: 800°C

Your perfect continuous combi cooker: extra modularity, extra flexibility

The ConduVec technology is manufactured in the form of cooking modules. The cooking modules are assembled to each other accordingly to suit your capacity needs and to build the exact tunnel oven you require. This extra modularity also makes it possible to combine different methods of heat transfer or to add specific modules to cool the product’s surface down.

A 100% UNIQUE COOKING SOLUTION DEVELOPED YOUR PRODUCT REQUIREMENTS

Does your product need a specific process? Do you have a special request? Contact us! Our application engineer can help you to find the best cooking solutions.Boost your capacity and quality by combining our different methods of heat transfer

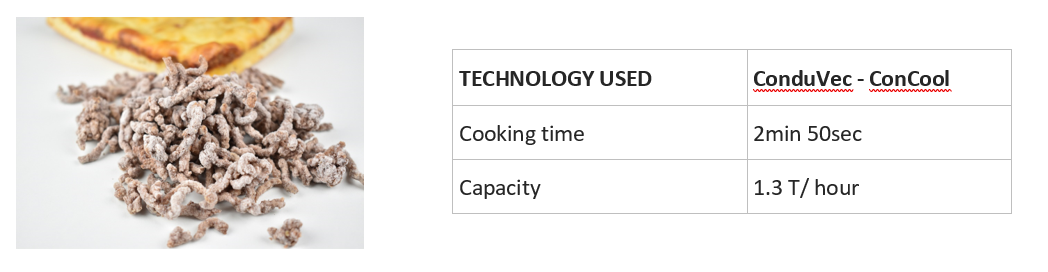

The example of associating our ConduVec – Continuous combi cooker with our ConCool – Surface cooler

By combining ConduVec and ConCool modules, CelsiusFOOD’s ground meats line can both cook and cool the meat in a single system. Thereby, you can cook the meat with a Maillard effect and keep the juices and fat during the process. At the outfeed, the meat is free-flowing and ready to be frozen or chilled before packaging.

An innovative cooking process for higher performances

In the case of our industrial cooking solution for ground meat products, the process is the following:

- 1) A vibrator or an agar screw spreads an even layout of meat on the Teflon belt

- 2) The ConduVec cooks the meats in about 2min 50sec. The temperature is 90°C after the cooking process. The length of the cooking zone is 6 meters.

- 3) The meat goes through a quality control zone, where a bridge is installed to separate the meat from the fat and juices.

- 4) The fat and juices are filtered and are maintained at 75°C

- 5) The meat goes through the cooling process (9 meters) during which the meat is cooled by conduction and convection. We spray the fat and the cooking juices by means of two ramps, a raked also mixes the meat before the end of the process.

Signature products

The benefits of combi heating in processing ground meat

Fully-cooked ground meats are ready-to-use and safe for consumption. Ground meats are cooked by individual free-flowing when the raw materials are ground frozen. The meat browns while it cooks in its juices.

When a modular pre-cooling step is integrated after the Combi oven, rendered fat and drippings are continuously collected from the meat. These juices are added to the cooked ground meat during the pre-cooling step.

Optimal cooking technology for your chicken-based products

Solid and non-stick conveyors are excellent for sticky poultry products. Problems associated to sticking, weak colour and marks from mesh-belts disappear. Broiling in static air, unlike forced air, causes browning with less dehydration and without shadow effects.

Modular Combi ovens can be integrated with modules for pre-cooking, browning and automatic turning/flipping over of products. Uniting two or more thermal techniques provides greater flexibility.

The best meatballs come from a CelsiusFOOD line

Spheric products like meat balls are seared by direct contact with a heated Teflon belt. At the same time, broilers contribute to all-round browning in dry static air. Static air, unlike forced air, eliminates dehydration and the “thewy” skin appearance caused by moving air. Modules for pre-steaming, flipping and additional searing can be added to modular Combi ovens.